Lynx-320

A compact industrial workhorse.

Designed to run every day.

Lynx-320 is the mini workhorse for industrial printing farms.

It combines consumer-like speeds with industrial reliability, ensuring warp-free production of

PA-CF and PA-GF parts.

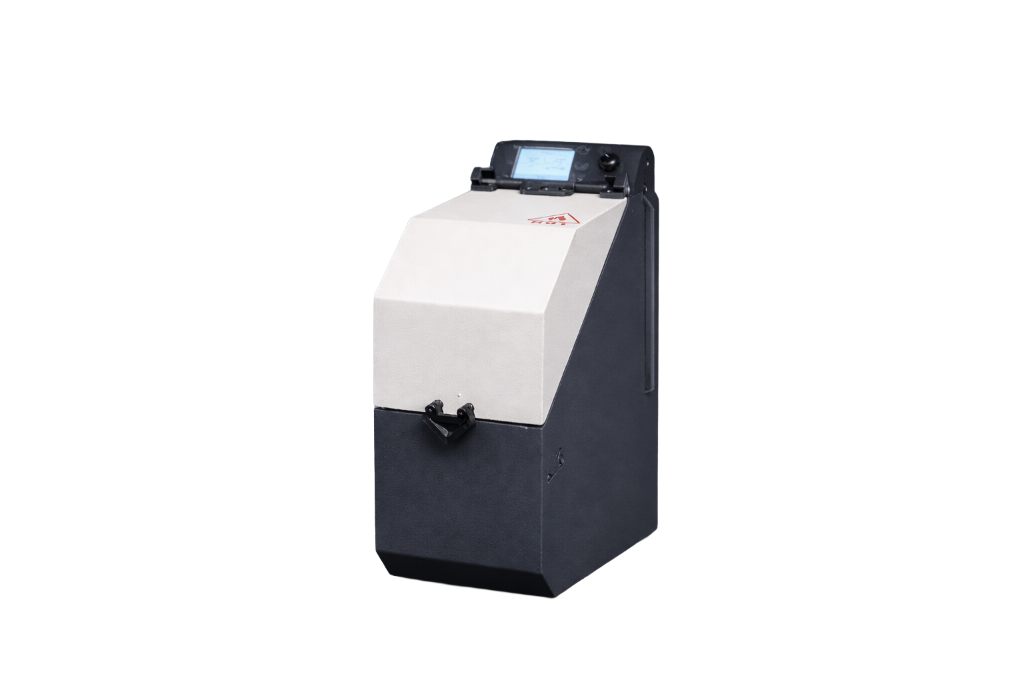

Lynx-Dry

Moisture is the enemy of engineering-grade materials. Lynx-Dry actively conditions your filament during printing, ensuring valid mechanical properties and the best possible surface finish.

Where Lynx-320 fits.

The Future Pipeline

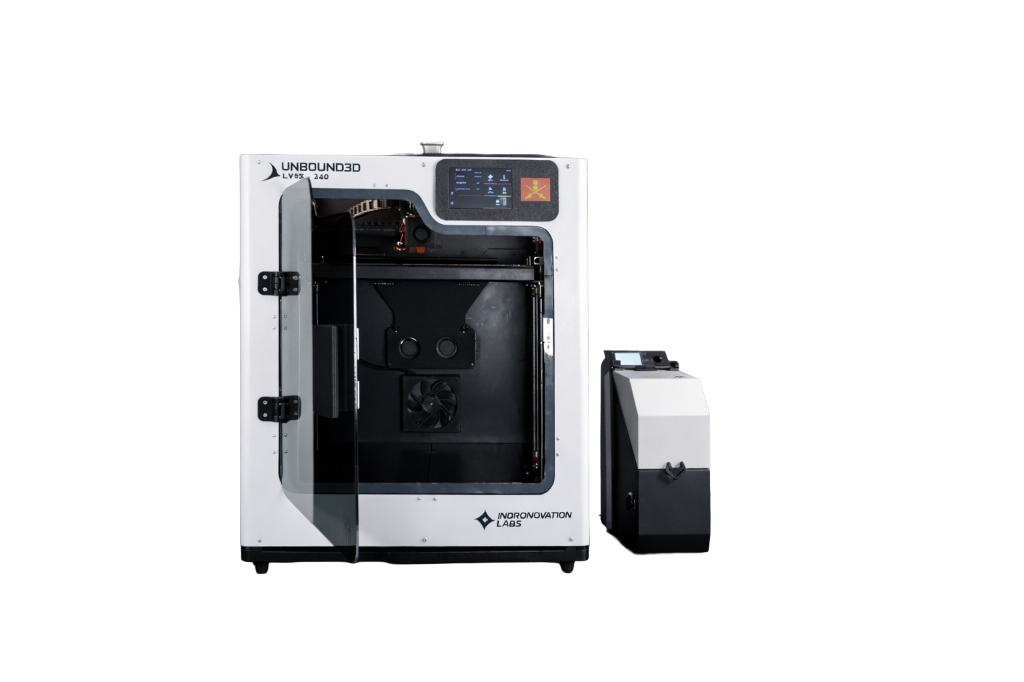

Unbound Workhorse

500mm cubic volume for large-scale enterprise production. Features a 100°C heated chamber and 200°C bed for high-temperature thermoplastic compatibility.

Next-Gen IDEX

Focused on complex assemblies with soluble supports, mirror printing for doubled throughput, and reduced material waste via optimized support generation.